Forno de sinterização de carburo cimentado em metalurgia em pó 6MPA 1600°C

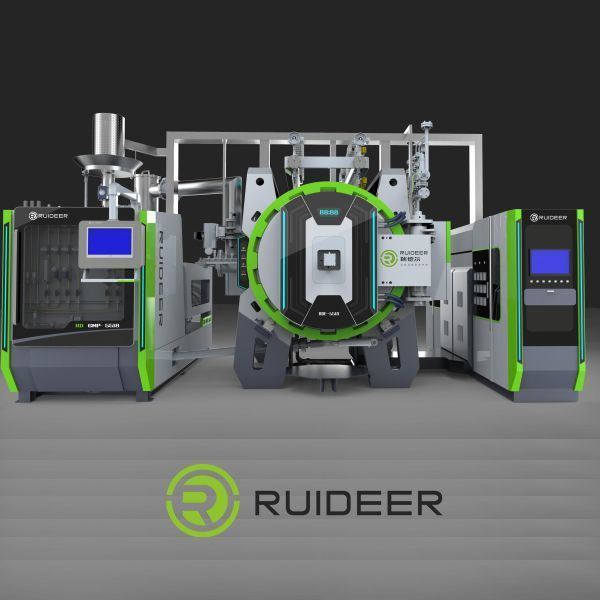

Zhuzhou Ruideer Intelligent Thermal Equipment Co., Ltd.localizado no Parque Tecnológico Ruideer, Distrito de Tianyuan, província de Zhuzhou Hunan, fundado em 2011, cobrindo uma área de mais de 19.000 metros quadrados.

Atualmente, a Ruideer desenvolveu duas tecnologias essenciais de deposição química de vapor e de alta temperatura e alta pressão, com fornecimento deForno de sinterização a vácuo eForno de revestimento CVD.

Os nossos principais produtos incluem:Forno GPS,Forno de sinterização a vácuo MIM,Forno de sinterização de carburo de silício/nitruro cerâmico,Forno de revestimento por carburo de silício,Ferramenta de corte de carburo cimentadoe a solução "chave na mão" para a ferramenta de corte de carburo cimentado ((A partir de pó RDP, máquina de prensagem, forno de sinterização, máquina de corte, máquina a laser, instrumentos de ensaio metalográfico, matriz de sabotamento,Máquina de limpeza por ultra-som para forno de revestimento CVD).

O Forno de Sinterização a Pressão de Gás (forno GPS) foi premiadoCampeão Nacional de FabricaçãoProduto,amplamente utilizado em carburo cimentado, não-cerâmica, semicondutores, aeroespacial, fabricação de automóveis, armas e outros domínios, exportado para os EUA, Rússia, Japão, UE, Ucrânia, Coreia do Sul,Vietname e outros paísesO que faz da Ruideer uma marca conhecida na indústria.

Metalurgia de póé um processo que utiliza pós metálicos (ou misturas de pós metálicos e não metálicos) como matérias-primas para fabricar materiais metálicos, materiais compostos,e vários tipos de produtos através da formação e sinterizaçãoComo a metalurgia de pó compartilha semelhanças com a produção de cerâmica, também é chamada de método cermet.

SinterizaçãoO processo de sinterização é um processo fundamental na metalurgia de pó.A sinterização é dividida em sinterização de um único sistema e sinterização de vários sistemas- na sinterização em fase sólida, quer em sistema único quer em sistema múltipla, a temperatura de sinterização é inferior ao ponto de fusão dos metais e ligas contidos;enquanto em sinterização em fase líquida de multi-sistemas, a temperatura de sinterização é inferior ao ponto de fusão dos componentes refratários, mas superior ao ponto de fusão dos componentes fusíveis.A sinterização é efectuada numa atmosfera protetoraPara além dos métodos de sinterização ordinários, existem também os métodos de sinterização de embalagem solta, infiltração de fusão (infiltração de metal na estrutura de sinterização) e prensagem a quente (combinação de prensagem e sinterização).

Os principais parâmetros do equipamento:

| Tipo de forno |

Tipo horizontal ((Pressão de trabalho máxima:58bar/98bar |

| RDE-3312-6 |

RDE-4412-6 |

RDE-5512-6 |

RDE-5518-6 |

| Espaço útil (W*H*L) |

300*300*1200 mm |

400*400*1200 mm |

500*500*1200 mm |

500*500*1800 mm |

| Carga máxima |

300 kg |

500 kg |

1200 kg |

1500 kg |

| Classificação de potência |

320 KVA |

320 KVA |

430 KVA |

600 KVA |

| Zona de aquecimento |

2/3 das zonas |

3 Zonas |

3 Zonas |

3 / 4 Zonas |

| Tempo de arrefecimento |

≤ 5h |

≤ 6h |

≤ 7h |

≤ 8h |

|

Forno vazio, arrefecimento a partir de uma temperatura de sinterização de 2100°C a 100°C.

(temperatura da água≤26°C, pressão da água 2-3bar, 55bar ((95bar) ≤Ar pressão≤58bar ((98bar).

|

| Vida de serviço |

20 anos/6000 ciclos de forno |

| Temporário de trabalho máximo |

1650°C |

| Medição da temperatura |

Projeto especial Termócopo de alta temperatura W-Re5/26 |

| Grau máximo de vácuo |

1 Pa (em fornos frios, vazios e secos) |

| Taxa de vazamento |

3Pa/h (valor médio no forno frio, vazio e seco) |

| Gás de entrada |

N2, Ar, |

| Funções |

Detecção automática de fugas de pressão positiva e de pressão negativa

Sinterização a vácuo

Sinterização a pressão parcial (estática, dinâmica)

Sinterização sob pressão

Refrigeração rápida

Controle totalmente automático e bloqueio de segurança, aquecimento contínuo de ponto de ruptura, controlo remoto sem fios e autodiagnóstico

|

Problemas no processo de sinterização deFerramentas de carburo cimentado.

1O excesso de carbono na liga, ou seja, o magnetismo do cobalto da própria mistura é elevado ou mesmo carburizado, o carbono no papel de carbono é absorvido, a parafina residual é rachada,e a camada de isolamento absorve parafina, o que resulta numa elevada concentração de carbono na atmosfera, etc.

2- carvão insuficiente na liga, ou seja, o magnetismo do cobalto da própria mistura é baixo, o produto prensado é armazenado por muito tempo, o forno perde água, o material de contacto é utilizado incorretamente,etc..

3. Uma elevada concentração de gás que contém carbono penetra nas partes fracas do produto (as bordas e os cantos do produto são frequentemente de baixa densidade ou têm um efeito elástico grave),e em contacto com o cobaltoO carbono precipitado destrói a continuidade da liga, fazendo com que a liga "descasque"

4A densidade do produto prensado é desigual; o teor de carbono em diferentes partes do corpo sinterizado é diferente; o barco é desigual, a atmosfera de sinterização é desigual,e a temperatura de sinterização é desigual

5. sobrequeima - a temperatura de sinterização é demasiado elevada; existem óxidos na chapa verde prensada que são difíceis de reduzir,e só podem ser reduzidos a uma temperatura mais elevada após a fase líquida aparecer.A pressão do gás gerada pela redução é superior à resistência da contração da fase líquida; os detritos na folha verde prensada, tais como detritos de liga, folhas de ferro,fios de cobre, etc.

6. o gás gerado pela redução de impurezas de óxido a alta temperatura ou o gás do forno que entra no corpo sinterizado, quando a liga se solidifica, não tem tempo de escapar,e é dispersado e permanece na liga, e a pressão do gás não é suficiente para formar bolhas e tornar-se buracos

7. o gás gerado pela redução de impurezas de óxido a alta temperatura ou o gás do forno que entra no corpo sinterizado, quando a liga se solidifica, não tem tempo de escapar,e é dispersado e permanece na liga, e a pressão do gás não é suficiente para formar bolhas e tornar-se buracos.

Mais sobre as diferenças entre o forno de sinterização HIP e o forno de sinterização a pressão de gás

Descrição das principais funções:

- Detecção automática de fugas de pressão positiva e negativa antes da abertura do forno;

- Ar função de desaxamento da pressão diferencial do gás transportador;

- Ar função de desaxamento da pressão diferencial do gás transportador;

- Função de desoxidação micro positiva de H2;

- Função de sinterização a vácuo;

- Função de sinterização parcial;

- Função de sinterização estática a pressão parcial;

- Função dinâmica de sinterização a pressão parcial;

- Função de processamento de produtos na atmosfera gasosa;

- Função de sinterização sob pressão;

- Função de sinterização sob pressão;

- Função de controlo totalmente automática;

- Função de bloqueio de segurança;

- Função de reaquecimento do ponto de ruptura;

- Função de diagnóstico remoto sem fios;

Forças do equipamento:

- O equipamento tem a função de aquecimento contínuo no ponto de ruptura, função automática de desoxidação, função de diagnóstico remoto sem fios e função de ensaio a baixa temperatura;

- O tubo principal de vácuo do equipamento e o sistema de remoção de cera estão equipados com filtros (produtos patenteados) para evitar que a poeira e as impurezas poluam o óleo da bomba,e prolongar o tempo de troca de óleo e a vida útil da unidade de bomba.

- Conveniente e inteligente: a interface de controlo do forno de sinterização pode ser monitorizada através do telemóvel,e o estado de funcionamento do equipamento pode ser controlado e compreendido a qualquer momento e em qualquer lugarFunção de operação totalmente automática de uma chave, uma pessoa pode supervisionar vários dispositivos, produção inteligente e pode ser conectada ao sistema de gerenciamento ERP.

- Sistema completo de serviço pós-venda: fornecer uma linha telefónica 24 horas por dia. Após receber a notificação de falha do cliente, uma solução será proposta dentro de 2 horas,e se for um caso urgente que precise de manutenção no localA tripulação técnica chegará dentro de 12 horas após o embarque do avião, com pessoal experiente e profissional do serviço pós-venda.Eles não são apenas responsáveis pela instalação e comissionamento dos produtos da empresa, mas também completam as operações de pós-venda e manutenção de fornos de sinterização para fabricantes nacionais e estrangeiros.

- Serviço conveniente: os utilizadores podem testar os produtos no local da Ruideer, se tiverem necessidades.

- Instalação rápida: sob a condição de que a água, a eletricidade e o gás do usuário estejam disponíveis, a instalação, depuração e produção podem ser concluídas em 20 dias.

- Equipamento de ensaio da empresa: Para garantir a qualidade dos produtos, a Ruideer está equipada com detectores de vazamento de espectrómetro de massa de hélio importados,que são utilizados para testar as superfícies de vedação do equipamento antes de sair da fábrica para evitar pequenos vazamentos e alcançar um estado de vedação perfeitoO equipamento de ensaio de precisão profissional (atualmente o fabricante de equipamento de fornos de sinterização,equipado apenas por Ruideer), para satisfazer a rápida pré-aceitação dos clientes no local de produção e para controlar o forno sinterizado O bloco de amostra é testado,e os resultados de desempenho do bloco de amostra da placa de controle do forno podem ser testados a tempo, e o nível de detecção atingiu o padrão de uma pequena e média fábrica de ligas.

Documentação do equipamento an Arquivos técnicos

- Manual de operação e manutenção (O&M)

- A instalação

- Disposição dos equipamentos

- Manual de instalação do equipamento completo, desenho de instalação do equipamento e requisitos para água, electricidade e gás.

- As condições externas (água, electricidade e gás) necessárias para a instalação do forno de sinterização devem ser fornecidas pelo comprador de acordo com as exigências do fornecedor.

- Desenhos mecânicos

- Desenhos de peças frágeis do equipamento

- Diagrama esquemático elétrico

Preparação do comprador

- Preparado pelo comprador antes da instalação:

- Serviços necessários para o levantamento e descarregamento do equipamento do forno de sinterização instalado.

- A ligação da fonte de alimentação ao ponto de ligação situado fora do gabinete de alimentação.

- Os tubos de entrada e de retorno da água de arrefecimento ligados ao equipamento, vários tubos de gás de processo, tubos de abastecimento de ar comprimido e de argônio de alta pressão, tubos de escape de gás de alta pressão,tubos de descarga de gases de escape da bomba, etc.

- Fornecimento e armazenamento de gás pressurizado e redução da pressão do gás pressurizado para a faixa de pressão correspondente, o equipamento necessário e a válvula redutora de pressão de cada gás de processo.

- Se necessário, medir a poluição do gás pressurizado.

- Dispositivo de abastecimento de água de emergência em caso de interrupção da água de arrefecimento.

- O vendedor fornece apenas materiais de certificação para a produção de recipientes sob pressão na China.

- O meio de trabalho, os materiais de processo e outras matérias conexas necessárias para a aceitação.

- As outras matérias não mencionadas, que não estão incluídas no âmbito do fornecimento, devem ser preparadas pelo comprador.

Normas de concepção

O equipamento é concebido em conformidade com os requisitos do Instituto de Supervisão Técnica e de Qualidade para recipientes sob pressão e é qualificado após ensaio sob pressão e enviado.O projecto e a construção eléctricos cumprem as normas nacionais.

As opções horizontais e verticais estão disponíveis:

Testes pré-instalação e pré-aceitação

O equipamento é totalmente montado em nossa fábrica, incluindo todos os tubulações, tubulações de vácuo, tubulações de gás de processo, tubulações de água de resfriamento, tubulações de ar comprimido, etc.Os ensaios prévios podem ser realizados após a instalaçãoNo local do cliente, as tubulações, para além do equipamento, são fornecidas pelo cliente.O cabo principal que liga o gabinete de alimentação é fornecido pelo cliente.Após a instalação, realizamos testes de vazio e de vazamento de pressão positiva em todo o equipamento, bem como testes de função mecânica e elétrica.

Desmontagem e transporte

O equipamento será desmontado em várias partes grandes, embalado numa caixa de madeira padronizada e carregado no veículo de transporte.

Instalação e comissionamento no local do cliente

O engenheiro pós-venda da Redeer irá liderar a equipe para concluir o comissionamento, a queima de testes de produtos e outros trabalhos dentro de 20 dias úteis.O cliente deve fazer os preparativos adequados e fornecer as ferramentas necessárias, tais como equipamento de elevação e elevação. e fornecer apoio de pessoal de instalação (recomenda-se ter 1 pessoal mecânico e 1 pessoal elétrico).

Aceitação final

Após a instalação e colocação em serviço, o equipamento pode ser finalmente aceite em conformidade com os requisitos do contrato técnico.

Formação

Os nossos engenheiros pós-venda fornecerão um treinamento sistemático e completo no local, incluindo operação, manutenção, solução de problemas, etc.

Entrega de dados técnicos

Para assegurar a operação segura e a manutenção dos equipamentos, os seguintes dados técnicos serão fornecidos aos clientes:

1. Disposição da instalação do equipamento

2. Manual de utilização

3Lista de peças de reposição

4Desenhos eléctricos

5Manual do componente

Perguntas frequentes

P: É uma fábrica ou uma empresa comercial?

R: Somos o principal fabricante de fornos de vácuo de alta temperatura da China, com mais de 15 anos de experiência.

P: Você tem serviço de personalização ou OEM?

R: Sim, temos uma poderosa equipa de I&D e equipamento de alta tecnologia. Assim, não só podemos fornecer o modelo normal, mas também o forno personalizável como o repuirment dos nossos clientes.

Qual é a sua vantagem?

P: Qual é a sua vantagem?

A:

Resposta rápida ao seu pedido.

L Alto controlo de qualidade

L Cadeia de abastecimento estável

L Entrega atempada

Excelente serviço pós-venda

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!